Understanding the LiftMaster LA500 Series Gate Operator

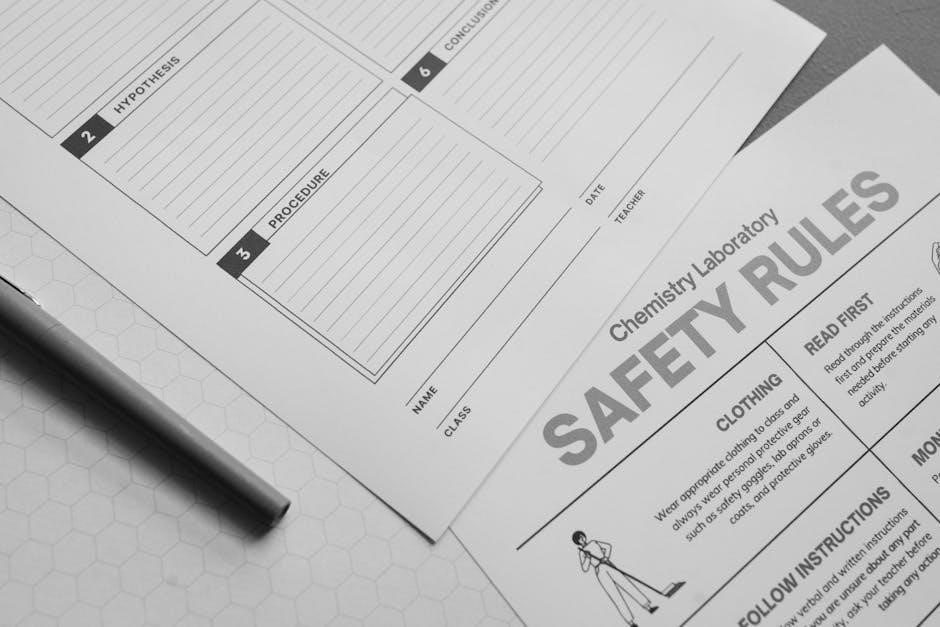

The LiftMaster LA500 series, including LA500 and LA500-S models, comprises vehicular swing gate operators. These residential/light commercial units are UL 325 Listed, ensuring safety and performance. Installation and servicing require a trained gate systems technician.

Overview of LA500 and LA500-S Models

The LiftMaster LA500 and LA500-S models represent highly capable vehicular swing gate operators, specifically engineered for both residential and light commercial applications. While the visual appearance of a specific model might differ from illustrations provided in documentation, their fundamental operational principles remain consistent. Critical instructions, such as those found in the “LA500 & LA500-S VEHICULAR SWING GATE OPERATOR INSTALLATION MANUAL,” explicitly state that installation and subsequent servicing must be performed solely by a trained gate systems technician. This strict requirement underscores the inherent complexity and the paramount importance of adhering to safety standards. For comprehensive usage details, owners and service personnel can consult the “LiftMaster LA500 Residential / Light Commercial Swing Gate Operator User Manual” and the overarching “LiftMaster LA500 and LA500-S Vehicular Swing Gate Operator Instruction Manual.” These crucial resources provide in-depth information on all aspects, from initial setup procedures to advanced feature utilization, ensuring optimal performance and system longevity. The LA500 series, including variations like LA500PKGUL, LA500DC, and LA500DCS, stands as a testament to LiftMaster’s dedication to delivering secure and reliable gate automation solutions.

Available Product Guides and UL 325 Listing

The LiftMaster LA500 series gate operators are distinguished by their essential UL 325 Listing, a critical certification underscoring adherence to rigorous safety standards for vehicular gate operators. This listing is paramount for ensuring the safe and reliable operation of the entire gate system, protecting both users and property. To facilitate proper installation and ongoing maintenance, a variety of comprehensive product guides are readily available. These include the “LiftMaster Model LA500UL Product Guide ౼ Spanish” and an informative “UL 325 Listed Gate Operator Feature Chart ౼ English,” which detail operator capabilities and regulatory compliance. Furthermore, essential user and instruction manuals, such as the “LiftMaster LA500 Residential / Light Commercial Swing Gate Operator User Manual,” are available for direct download. These resources are indispensable for fully understanding the operator’s features, ensuring correct installation, and maintaining continuous compliance with vital safety regulations. Providing guides in multiple languages, like Spanish, significantly enhances accessibility, ensuring all critical information is effectively communicated. These foundational documents are crucial for trained technicians and owners of LA500 and LA500-S models, emphasizing professional installation and meticulous servicing as outlined by LiftMaster.

Accessing Official LiftMaster LA500 Manuals and Downloads

Official LiftMaster LA500 manuals and downloads are readily available for various models. Users can access essential documentation, including installation guides and product manuals in PDF format. These resources provide comprehensive information for setup, operation, and troubleshooting, ensuring proper gate operator functionality and compliance with safety standards.

Downloadable PDF Manuals and Specific Revisions (2015, 2014, 2013)

For users seeking detailed information on their LiftMaster LA500 series gate operators, a comprehensive collection of downloadable PDF manuals is readily available. These essential documents cater to various models, including LA500PKGUL, LA500DC, and LA500DCS, providing crucial instructions for installation, operation, and maintenance. Accessing the correct manual ensures that owners and professional technicians can effectively manage their gate systems.

The availability of specific revisions is particularly beneficial for addressing different product iterations and updates. Key manual revisions from past years are archived and accessible, offering historical context and relevant guidelines. For instance, users can find the “liftmaster-la500-manual, 2015 Rev C.pdf,” which represents a specific version of the instruction manual released in that year. Similarly, older but equally important revisions like the “liftmaster-la500-manual, 2014 Rev B.pdf” and “liftmaster-la500-manual, 2013 Rev G.pdf” are also provided. These older documents remain vital for owners of units manufactured during those respective periods, ensuring they have the precise information applicable to their particular gate operator. Whether needing a user manual for residential/light commercial swing gate operators or detailed installation guides, these downloadable PDFs offer invaluable support. They are critical resources for understanding the intricate workings of the LA500 and LA500-S models, facilitating proper setup and troubleshooting.

Installation Manuals in English, Spanish, and French

To ensure broad accessibility and proper installation across diverse user bases, LiftMaster provides comprehensive installation manuals for the LA500 series in multiple languages. These crucial documents are available in English, Spanish, and French, catering to a wide range of technicians and homeowners. For instance, the “LiftMaster LA500PKGUL, LA500DC, LA500DCS Installation Manual ౼ English” offers detailed instructions for these specific models. Similarly, users requiring Spanish guidance can refer to the “LiftMaster LA500 Installation Manual-Espanol,” which covers essential setup procedures in their preferred language. French-speaking installers are also supported with dedicated manuals, such as those for the LA500U, LA500PKGU, LA500DCU, and LA500DCSU vehicular swing gate operators. These multilingual resources underscore LiftMaster’s commitment to user-friendly support. They emphasize that the product “IS TO BE INSTALLED AND SERVICED BY A TRAINED GATE SYSTEMS TECHNICIAN ONLY,” highlighting the importance of professional installation. The manuals provide step-by-step guidance, ensuring that the light commercial/residential DC vehicular swing gate operator is set up correctly and safely, regardless of the installer’s primary language. This availability helps prevent misinterpretations and promotes adherence to safety standards during initial setup of the LiftMaster LA500 and its variants.

Quick Start Guides and Comprehensive Wiring Diagrams (LA500UL)

For expedited setup and detailed electrical connections, LiftMaster provides both Quick Start Guides and comprehensive Wiring Diagrams, particularly for the LA500UL model. The “LA500PKGU-QUICK-START-GUIDE.pdf” is an excellent resource for installers seeking to rapidly deploy the gate operator, offering concise instructions to get the system operational efficiently. Beyond the initial setup, understanding the intricate electrical system is paramount, which is where the “LiftMaster LA500UL Wiring Diagram Product Manuals” become indispensable. These diagrams are critical tools for any trained gate systems technician. They meticulously detail the connections, including diagnostic points and terminal blocks such as SBC, OPN, CLS, STP, COM, and EYE, which are essential for correct wiring and troubleshooting. Such comprehensive diagrams ensure that all components, from the control box to safety sensors, are connected precisely, adhering to safety standards. These resources are designed to simplify complex electrical installations and aid in diagnosing any potential issues, making the installation process smoother and more reliable for the LA500UL and related models. They highlight the technical aspects necessary for a robust and safe gate operation.

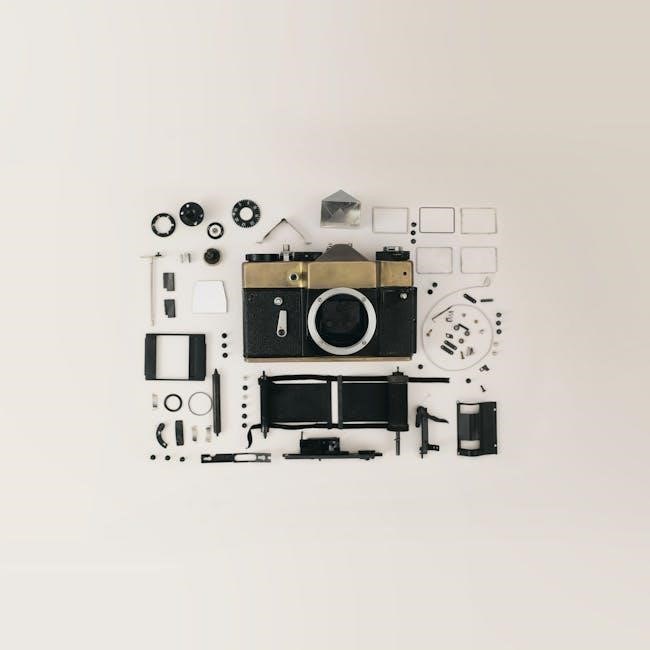

Key Components and Initial Installation Setup

Initial installation of the LiftMaster LA500 includes the standard control box with two 12Vdc 7AH batteries, keys, post and gate brackets, warning signs, and the installation manual. A crucial component is the monitored retro-reflective photoelectric sensor, vital for safety.

Standard Control Box, Batteries, and Essential Accessories Included

The LiftMaster LA500 gate operator package includes several crucial components for initial setup and ensuring reliable performance. Central to the system is the standard control box, which meticulously manages all gate operations and expertly houses its essential electronic circuitry. Powering the unit are two 12 Vdc 7AH batteries, critical for consistent functionality and providing necessary backup during any power outages, thus ensuring uninterrupted service. For mechanical mounting, the kit provides both a sturdy post bracket and a durable gate bracket, explicitly designed for secure and stable attachment of the operator arm to the gate structure. Users will also find two keys, offering convenient options for manual override or access control. To prioritize safety, two prominent warning signs are included, which must be displayed around the gate’s operational area. A comprehensive warranty card details product support and coverage information. Furthermore, a detailed installation manual guides trained technicians through the precise setup procedures for the LA500. The system integrates a specific battery tray, Model K10-36183, explicitly designed to house the included batteries effectively, completing the core package for a robust, functional installation.

Monitored Retro-Reflective Photoelectric Sensor and Other Parts

Beyond the core control box and batteries, the LiftMaster LA500 system integrates crucial safety and operational components. A key element is the LiftMaster Monitored Retro-Reflective Photoelectric Sensor, vital for detecting obstructions in the gate’s path and ensuring compliance with UL 325 safety standards. This sensor helps prevent accidents by stopping or reversing the gate’s movement if an object is detected. To facilitate proper electrical connections, the system also includes a junction box, a terminal block connector, and a watertight extension cable connector, ensuring secure and weather-resistant wiring. These components are essential for the reliable operation and longevity of the gate operator, particularly in outdoor environments. Furthermore, for specific installations, especially those utilizing solar power, it’s advised to disconnect the expansion board. The operator also relies on internal parts such as a drive screw, which aids in the gate’s opening and closing mechanism, and potentially a hall effects device, which can be a point of troubleshooting if issues arise. LiftMaster recommends using low power draw accessories to optimize energy consumption.

Advanced Features and Programming

The LiftMaster LA500 offers advanced programming capabilities, including setting gate open limits with a remote control and seamless integration with the LiftMaster Internet Gateway for enhanced control and monitoring of your gate system.

Setting Gate Open Limits Using Remote Control

Setting the gate open limits on your LiftMaster LA500 operator using a remote control is a crucial step for defining the gate’s maximum travel. This process ensures the gate stops precisely at its desired fully open position, preventing over-travel and potential damage. To initiate this, locate the designated programming button on the operator’s control board or within its interface. You will need to press and hold this button until the system’s LED light begins to blink, indicating that the operator has entered its learn or programming mode for limit adjustments. This visual cue confirms the system is ready to receive input for the open limit. Once the LED is actively blinking, proceed by taking your remote control. Press the specific button on the remote that is designated for the open function, often labeled “Open” or “Up.” As soon as this button is pressed, the gate should commence movement towards its fully open position. It is imperative to allow the gate to complete its travel to the exact desired open point before releasing the remote button or confirming the setting. The system will then register this position as the new open limit, storing it in the operator’s memory. This remote-controlled method provides a convenient and efficient way to precisely calibrate your LA500 gate’s operational parameters, ensuring smooth and reliable functionality for daily use.

LiftMaster Internet Gateway Pairing and Registration Process

The process of pairing and registering your LiftMaster Internet Gateway with an LA500 gate operator enables advanced smart control and remote monitoring capabilities. To begin, activate the learn mode on your LiftMaster Internet Gateway; it will remain active for a crucial three-minute window, ready to establish a connection with your system. During this critical period, you must initiate the learn mode on your primary LA500 gate operator. This is typically achieved by pressing its designated Learn button twice. Upon successful activation, the operator will emit an audible beep, confirming it has entered its own learn state and is now discoverable for pairing. For successful pairing, ensure the LiftMaster Internet Gateway is positioned within effective range of the primary operator. If both devices are correctly in learn mode and in suitable proximity, they will automatically attempt to pair. A successful programming will be clearly indicated by another beep from the operator, signifying that the secure connection has been established between them. Following this physical pairing, the next essential step involves registering the LiftMaster Internet Gateway. This final process is performed using an internet-enabled device, which allows you to link the gateway to your LiftMaster account for comprehensive remote access and management of your gate system, unlocking its full smart capabilities and convenience.

Troubleshooting, Maintenance, and Safety

Troubleshooting your LiftMaster LA500 involves diagnosing noise, battery issues, and error code 99. Maintenance includes greasing internal bearings; Always perform required safety testing to ensure reliable and secure gate operation.

Diagnosing Noise, Battery Issues, and Error Code 99

Diagnosing issues with your LiftMaster LA500 often involves addressing common problems like persistent noise, battery malfunctions, and specific error codes such as 99. If you encounter unusual noise, especially from the actuator arm near the end of its travel, it may indicate internal wear beyond just gate hinges. Users have reported noise persisting even after greasing external components, suggesting the drive screw inside the operator could be the source.

For battery-related troubles, the system can exhibit various symptoms, including the gate failing to open or operate inconsistently. Specific troubleshooting guides and videos are available to help identify and resolve these power supply issues, which might range from needing a simple battery replacement to checking connections or the charging system.

Error code 99 is a distinct diagnostic signal that users have reported. While its exact meaning requires consulting the official LiftMaster LA500 manual PDF or diagnostic resources, it has been observed occurring independently of environmental factors like sun exposure. If encountered, alongside checking photo eyes, a new control board might be considered as a potential solution if other diagnostics prove inconclusive. Accessing diagnostic codes is crucial for pinpointing the root cause.

Greasing Internal Bearings and Required Safety Testing

Proper maintenance of the LiftMaster LA500 includes periodic greasing of internal bearings to ensure smooth operation and longevity. Users often inquire about the specific type of grease suitable for these components, such as general, heavy-duty, or lithium-based options. While external hinges and bearings are frequently addressed, noise emanating from the gate actuator arm itself, especially near the end of its travel, suggests that internal parts like the drive screw might require attention. Consulting the official LiftMaster LA500 manual PDF is crucial for identifying the correct lubrication specifications and procedures.

Beyond lubrication, the manual explicitly states the importance of required safety testing after any servicing or maintenance. This includes verifying the proper function of all safety features, such as the monitored retro-reflective photoelectric sensor and gate limits. Adhering to these safety testing protocols is not only essential for the operator’s performance but also vital for user safety and compliance with industry standards, like UL 325. Always refer to the latest installation and maintenance guides for detailed instructions on both greasing and comprehensive safety testing to maintain your gate operator effectively.